Ageing of UV lamps and UV LEDs

Measuring the irradiance of high power UV light sources is essential for UV radiation curing processes as they require precise dose control. UV curing uses UV light for polymerization by photoinitiators in materials, where exposure is critical. UV radiometers are used to accurately measure UV intensity and dose (J/cm²), and the detectors must have high spectral sensitivity to meet the requirements.

Types of light sources used to generate UV radiation:

- High-power gas discharge lamps:

These lamps produce strong UV radiation using high-temperature vaporized mercury in a quartz tube, with the possibility of adjusting the spectral emission using doping metals. - High-power UV LEDs:

They offer advantages such as energy efficiency, immediate readiness for use and a long service life, although temperature-dependent wavelength stability and ageing effects must be taken into account.

Lifetime of UV lamps and UV LEDs

| Type of UV light source | Description | Typical lamp service life |

| UV lamp (low pressure) | Used in (water) disinfection | 8.000 - 12.000 hours |

| Amalgam lamps | Higher efficiency and longer service life | 12.000 - 16.000 hours |

| UV LED | Energy-saving. for smaller applications | 10.000 - 20.000 hours |

| UV LED modules | Modular units. customizable and efficient | 10.000 - 20.000 hours |

| High-pressure lamps | Very high UV intensity. broad spectrum | 500 - 2.000 hours |

| Pulsed xenon lamps | Intense UV light flashes for peak intensity | 1.000 - 3.000 hours |

| Excimer lamps | Specific. narrow wavelength ranges | 5.000 - 8.000 hours |

| UV lamp (medium pressure) | Suitable for industrial applications | 1.000 - 4.000 hours |

| UV lamp (medium pressure. doped) | Doped with iron or gallium for special spectra | 600 - 2.000 hours |

| Xenon short arc lamp | High intensity and broad spectrum | 500 - 2.000 hours |

Regular measurements are necessary due to the ageing of UV lamps and UV LEDs. But ...

Why do UV lamps age?

UV lamps age due to several physical and chemical processes:

- Electrode erosion: the electrodes in the lamp wear out over time due to the electrical discharge process, reducing their efficiency.

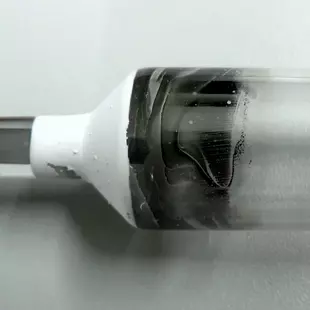

- Material evaporation: Materials within the lamp, such as mercury and tungsten, can evaporate and deposit on colder parts of the lamp, reducing light output through absorption.

- Phosphor consumption: In some UV lamps that use phosphor to convert UV light into visible light, the phosphor can degrade, reducing the light intensity.

- Solarization: UV radiation can change the lamp material, especially the quartz glass, over time, reducing the transmittance of UV light.

These factors combine to reduce the light output of the lamp over time, requiring regular maintenance or replacement.

And...

Why do UV LEDs age?

Like all electronic components, UV LEDs are also subject to ageing. As with all products, the product quality of UV LED lamps varies considerably. Over the service life of UV LED lamps, there is a continuous decrease in UV light output. This is referred to as degradation. The factors that influence the ageing of LEDs include, in particular, the operating temperature and the operating current. UV LEDs age for several reasons, which are mainly related to the inherent material properties and operating conditions:

- Thermal degradation: the heat generated during the conversion of electrical energy into light can damage the semiconductor materials of LEDs and reduce their efficiency.

- Oxidation and moisture: Exposure to oxygen and moisture can damage the materials in the LED, especially the electrodes and the compounds.

- Material fatigue: Repeated expansion and contraction due to temperature fluctuations can cause material fatigue, which affects performance

These factors combine to reduce the output of UV lamps and UV LEDs over time, meaning that their light intensity and lifetime are limited.

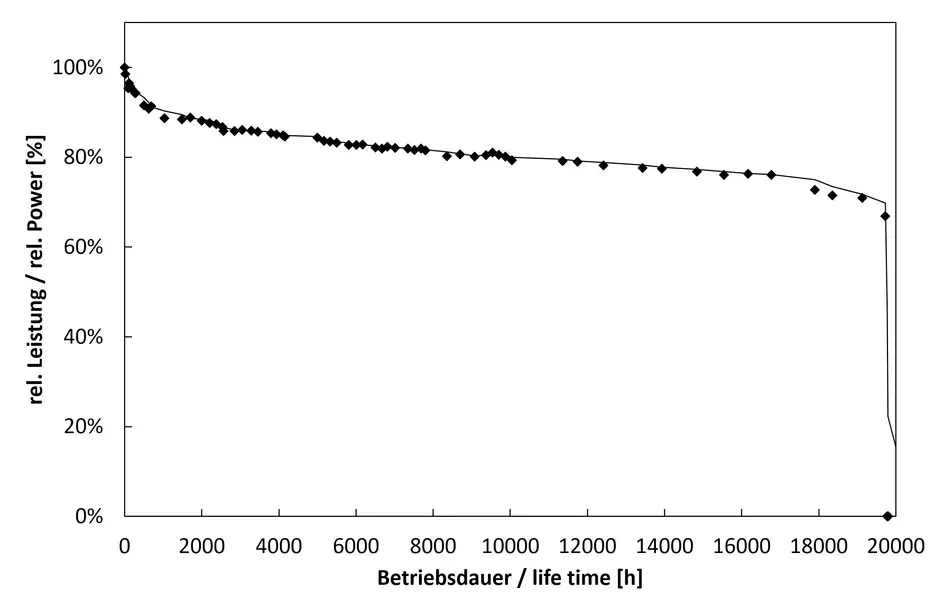

Right from the start, there is an exponentially decreasing degeneration behavior, which slowly approaches a limit value after a few thousand hours. A second failure mechanism is the spontaneous failure of UV LEDs.

Spontaneous failures of UV LEDs can be caused by several mechanisms, including electrostatic discharge (ESD), which can damage components through a sudden power surge. Wire bond failures can also occur, where the tiny wires connecting the LED chips to the terminals fail.

Faults in the semiconductor material itself, such as cracks or defects in the semiconductor layers, can also lead to the sudden failure of individual UV LEDs. These types of failure often occur without warning and lead to an immediate loss of function of the LED.

UV LEDs are considered superior to traditional UV lamps in some aspects of ageing:

- Durability: UV LEDs typically have a longer lifespan as they are less susceptible to thermal degradation and mechanical damage.

- Stability: They offer better wavelength stability over time because they are less affected by thermal fluctuations.

- Efficiency: UV LEDs use energy more efficiently and generate less waste heat, which further extends their service life.

The main differences between the ageing of UV lamps and UV LEDs:

The main differences in ageing are therefore in the way the different light sources process heat and material fatigue, which positively influences the efficiency and longevity of UV LEDs.

We are happy to help you select UV measuring devices to check the UV ageing of high-power gas discharge lamps and UV LEDs. Opsytec offers specially developed measuring devices that guarantee precise and reliable UV measurement and also enable ISO 17025-compliant calibrations.

The diagram illustrates the typical ageing curve of a UV LED, characterized by an initial sharp drop in performance in the first few hours of operation. After this initial decrease, the power loss stabilizes and follows a gradual, almost linear degradation over time. This continuous reduction in light emission continues until the LED reaches the end of its service life and finally fails completely without emitting any radiation: