Collimated Beam Device BSM-03 CBD

The „Guidance document on the impact of water treatment processes on residues of active substances or their metabolites in water abstracted for the production of drinking water“ of the European Chemicals Agency (ECHA) and the European Food Safety Authority (EFSA) provides a framework for risk assessment with regard to the authorization of active substances contained in plant protection products (PPPs) and biocidal products and the approval of these products.

The guidance enables the identification of actual health concerns that may arise from exposure to harmful compounds that may be formed during water treatment for drinking water production.

The focus is on common water treatment methods within the European Union (EU). The UV irradiation, according to the guideline, chapter 4.2.4.6. can be realized by the BSM-03 in a reproducible way.

The BSM-03CBD is a highly developed and robust irradiation chamber that has been specially designed for the time- or dose-controlled UV irradiation of liquid samples according to the colimated beam principle.

It is particularly suitable for applications in the field of UV disinfection and for carrying out scientific experiments to investigate the effects of water treatment processes on residues of active substances or their metabolites.

Based on UV irradiation using the colimated beam principle, the effects of water treatment processes on residues of active substances or their metabolites can be analyzed. This includes in particular the formation of transformation products (TPs).

The BSM-03CBD is ideal for carrying out UV disinfection tests and irradiating samples under controlled conditions. The radiation is emitted vertically downwards and illuminates the suspension evenly with the aid of a apertures.

In a continuously stirred volume of e.g. 150 mL and a water depth of 1.6 cm, samples can be treated with an exact UV dose of 100 mJ/cm².

With its high irradiance of a few mW/cm², the BSM-03CBD achieves the required UV dose in typically a few seconds to two minutes, enabling fast and efficient treatment of samples.

The chamber can also be safely opened during active operation to load and unload samples. The internal shutter is controlled by the UV-MAT to ensure exact dosing. Safety monitoring ensures that no UV radiation escapes outside the chamber.

The BSM-03CBD irradiation chamber is therefore a reliable and precise solution for scientific research and industrial UV disinfection applications. Its robust design, safety and user-friendly operation make it an indispensable tool in water treatment and chemical analysis.

Main features of the collimated beam device:

The BSM-03CBD is equipped with an ozone-free medium pressure lamp with an output of 1 kW. This lamp ensures uniform and high UV irradiation.

A robust and safe protective housing ensures safe operation and protection against UV radiation.

The large irradiation area is suitable for customer Petri dishes and magnetic stirrers for continuous mixing of the liquid.

- Reference UV sensor for dose-controlled operation to ensure precise UV doses

- A 2nd UV sensor enables easy system set-up

- The UV-MAT Touch allows easy handling and monitoring of the irradiation process

- Monitored & locking door: Safety mechanisms prevent the emission of UV radiation when the door is open.

- A base plate with screw threads allows easy measurement of the irradiation field and adjustment of the sample position.

- Leveling feet for precise, horizontal alignment of the chamber

- Pneumatic, automated plate shutter: For precise control of the irradiation time

- Operating hours counter for monitoring lamp life and planning maintenance.

- PC software: For data storage of raw data and short reports (PDF), incl. user administration and password protection (2 user levels).

TECHNICAL DATA Collimated Beam DEVICE

| Interior chamber | 60 x 40 x 25 cm |

| Dimensions | 130 x 62 x 76 cm |

| Weight | ~ 80 kg |

| Power consumption | 1200 W |

| Mains | 3 x 230/400 VAC, 16 A, CEE 400V 16A |

| Power factor | 0,9 |

| Operation temperature | 15 to 30 °C |

| Humidity | < 80%, non condensing |

| Lamp lifetime | 1.000 h to 3.000 h, typical |

| Number of lamps | 1 piece |

| Lamp type | mercury medium pressure |

| ozone free | yes |

| Sample temperature | Room temperature + ~ 2-5°C |

| Shutter control | Pneumatic, 4-6 bar |

| Cooling | 1 x DN 100 |

Background of a collimated beam device

A collimated beam device is used for precise and controlled experiments in the field of UV disinfection and UV irradiation of liquids. Jim Bolton, a renowned expert in this field, has made significant contributions to the development and distribution of such devices.

A collimated beam device produces a parallel beam of UV light that ensures uniform intensity over the entire beam area. The advantages of the parallel UV light beam are:

- uniform irradiation

- no different angles of incidence

- low reflection on the liquid surface

- a constant layer thickness and penetration depth

- simple radiometric measurement

- determination of the dose and fluence (spherical dose) from the irradiance

The dose describes the radiation energy that is incident on a surface element from one side. It differs significantly from fluence, which by definition considers a spherical incidence on a spherical surface element (from all directions).

In a UV reactor, a particle is irradiated from all spatial directions as it passes through the UV reactor. This is very difficult to determine experimentally. Therefore, the adjustment is carried out under the optimum conditions in a collimated beam device. In this device, the dose corresponds exactly to the fluence, as the geometry allows this. The unit of dose and fluence is J/m².

A CBD is mainly used in research laboratories to test the efficiency of UV disinfection under controlled conditions.

Here are the basic steps of how it works:

- Preparation: the samples to be tested (e.g. water, surfaces, air samples) are placed in suitable holders.

- Irradiation: The collimated UV beam is directed at the samples. The irradiation time and the UV dose are determined on the basis of the experimental requirements.

- Monitoring: sensors continuously measure the UV intensity to ensure that the samples receive a consistent and precise UV dose.

- Analysis: After irradiation, samples are analyzed to determine the effectiveness of UV disinfection. This can be done by microbiological testing or chemical analysis.

UV irradiation is often used for disinfection purposes. UV-C radiation has a wavelength of 100-280 nm and is known to damage DNA by triggering a reaction between two thymide molecules (dimer formation). This method is very effective for inactivating bacteria and viruses, depending on the UV permeability of the water. Either medium or low pressure UV lamps are generally used for UV disinfection.

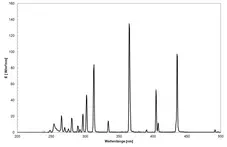

Medium-pressure UV lamps emit radiation in the range of 200 to 400 nm, while low-pressure UV lamps mainly generate radiation at 253.7 nm. To prevent the formation of unwanted by-products at lower wavelengths, MP lamps are equipped with quartz tubes that filter out wavelengths below 240 nm.

By using DVGW sensors and DVGW referenceradiometers, the intensity of the UV beam is continuously measured and monitored. This enables the exact dose applied to the samples to be determined.

For disinfection purposes, a UV dose of around 20-70 mJ/cm² is usually applied. These doses are relatively low and therefore photolysis reactions of organic micropollutants are generally not very effective under these conditions.

However, UV radiation is also used in combination with ozone, hydrogen peroxide or chlorine, which leads to the formation of hydroxyl radicals. Such processes are very effective in removing contaminants.