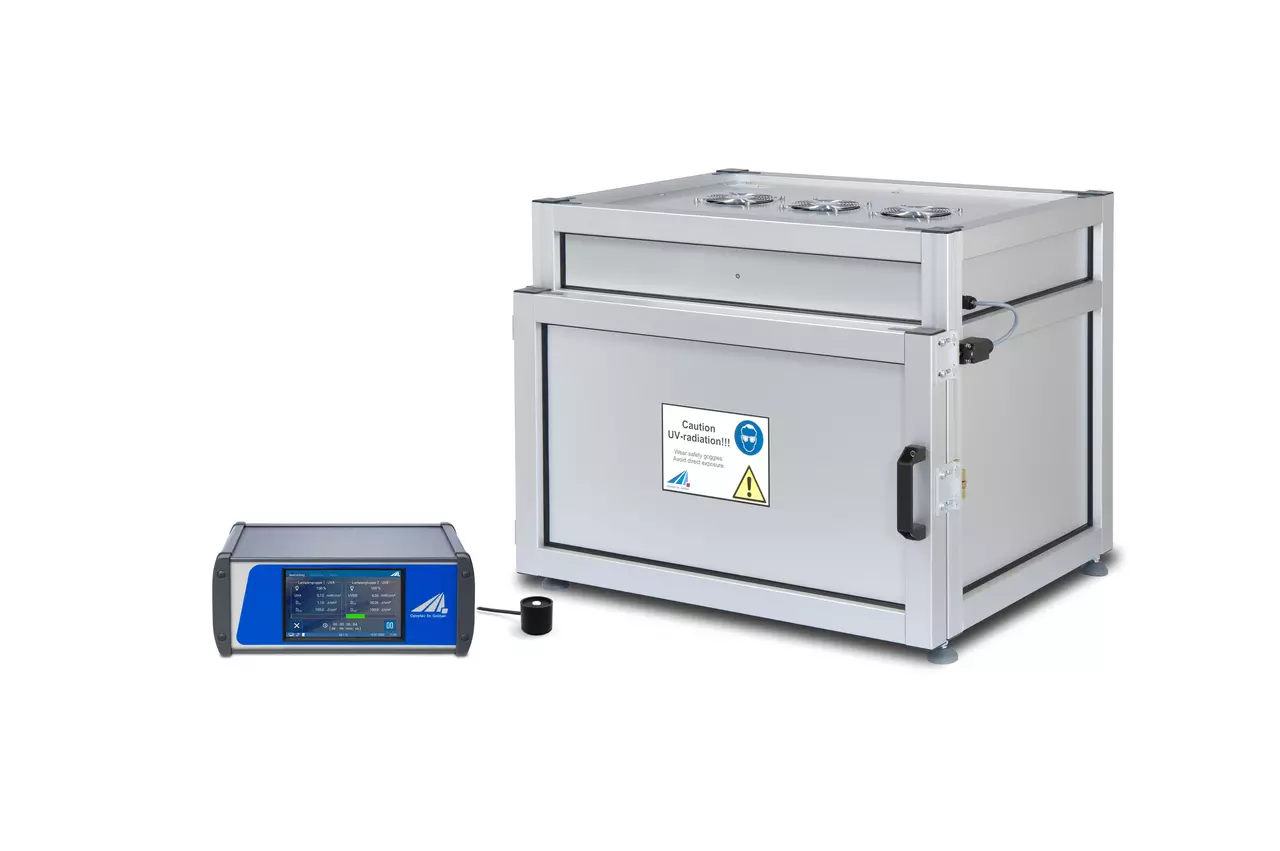

UV-LED CHAMBER BSL-03: Efficient UV irradiation for laboratory applications

The UV LED chamber BSL-03 is the second largest irradiation chamber in the BSL series. The high irradiance combined with the exact dose control offers a unique reproducibility for perfect results!

Due to the irradiance of up to 220 mW/cm², it is possible to use the most common UV curing adhesives or lacquers. For high irradiances, the UV LED chamber can be ordered completely with one LED wavelength. A particularly flexible application is possible when two separately controllable LED wavelengths are ordered.

Compared with our irradiation chambers of the BS series, the BSL-03 offers an irradiance that is 22 times as high. The high irradiance allows for extremely short exposure times. With the high homogeneity of the irradiation, the samples can also be positioned as needed.

Due to the typical characteristics for UV LEDs, such as “immediate start”, the dimmability and the high durability, the BSL-03 is ideally suited for medium-sized laboratory tests and curing of large components.

Thanks to the typical characteristics of UV LEDs, such as instant start, dimmability and long service life, the BSL-04 is ideal for medium-sized laboratory tests and the curing of large-area components.

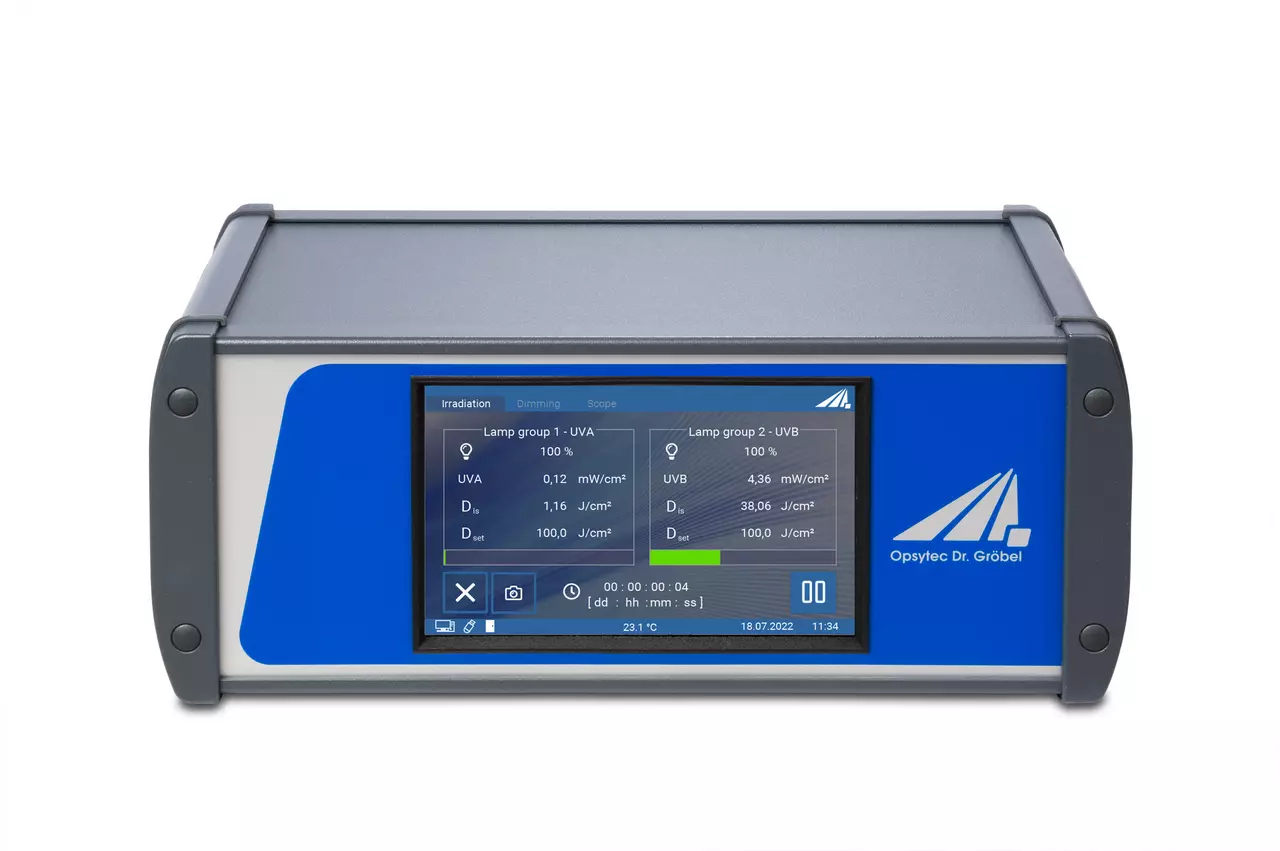

The dose control is already integrated in the UV-MAT Touch and UV-MAT control units in the BSL-03 UV LED chamber. By means of an optional sensor, the UV-MAT measures the irradiance continuously, and stops the irradiance at the set target dose.

The integrated timer already controls the irradiation precisely. For even better results, we recommend one of our calibrated UVA+ sensors. Dose control is already integrated in the UV LED chamber BSL-04 in the UV-MAT Touch and UV-MAT control units. With an optional sensor, the UV-MAT continuously measures the irradiance and stops irradiation when the set target dose is reached.

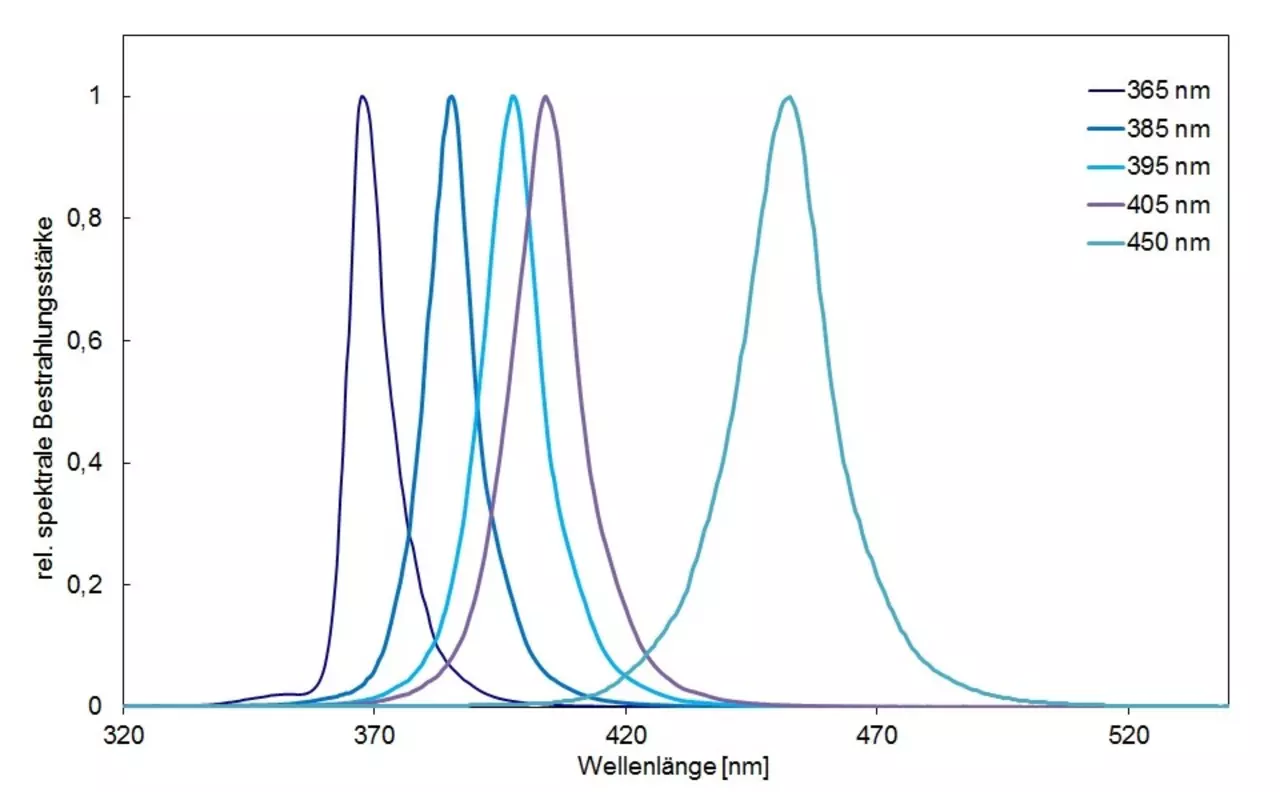

The wavelengths 365 nm, 385 nm, 395 nm, 405 nm and 450 nm are available for your application.

We offer the BSL-03 in two versions:

- 0 up to 220 mW/cm² (Version HO)

- 0 up to 110 mW/cm² (Version ECO)

The low heat input of the UV LEDs and the active air cooling of the sample chamber significantly reduce the thermal load on the samples. Due to the high homogeneity of the irradiation, the samples can be positioned as required.

The sample room has a floor space of 60 x 40 cm and a height of 25 cm. Parts that must be bonded or cured can be positioned easily on the movable sample carrier.

Thanks to the fully enclosed and monitored irradiation chamber, operating personnel are fully protected from UV radiation during han

APPLICATIONS OF HIGH-POWER UV-LED CHAMBER BSL-03

- UV curing and UV bonding

- Sealing and encapsulating

- Laboratory investigation

- Manual bonding

TECHNICAL DATA OF UV-LED CHAMBER BSL-03

| Interior chamber | 68 x 51 x 31 cm |

| Sliding sample carrier | 64 x 49 cm |

| Dimensions | 77 x 64 x 68 cm |

| Weight | ~ 70 kg |

| Power consumption | 1000 - 2000 W |

| Mains | 100 - 240 V, 50/60 Hz |

| Operation temperature | 10 to 40 °C |

| Storage temperature | -10 to 60 °C |

| Humidity | < 80% non-condensing |

| Cooling | air cooling |

| Sample temperature | Heating of the samples due to |

| high UV irradiation with | |

| long exposure | |

| Classification | group 0 according |

| DIN EN 12198:2000 | |

| Timer | 0,01 s to 9999 h |

| Resolution | 0,01 s |

| Dose control | with optional sensor |

| Internal security circuit | Over-temperature, door contact |

Zubehör

Publications at a glance

Our irradiation chambers are used in research, development, and production-

A selection of scientific publications is available here.