UV LED LedControl Touch

LedControl Touch is the further development of the proven LedControl S and offers maximum functionality with maximum user-friendliness. Equipped with a capacitive touch display in 5 or 7 inches, operation is intuitive, clear, and efficient.

The LED floodlights can be seamlessly integrated into automated processes via ModBus (TCP/IP, RS485) as well as digital and analog PLC interfaces.

Parameterization is intuitive and, if required, password-protected. The LedControl Touch can be used in laboratory, pharmaceutical, and industrial environments without any problems. The LedControl Touch records irradiation protocols directly to a storage device.

The LED output can be precisely adjusted between 2% and 100%. Short cycle times are possible thanks to the trigger input and internal timer, which can be set individually for each channel.

Wavelengths of 365 nm, 385 nm, and 395 nm are available for different UVA applications. For bonding behind window glass, for example, wavelengths of 405 nm to 450 nm are available.

Irradiance levels of up to 1.4 W/cm² are achieved on the surface to be irradiated. This high irradiance enables short processing times.

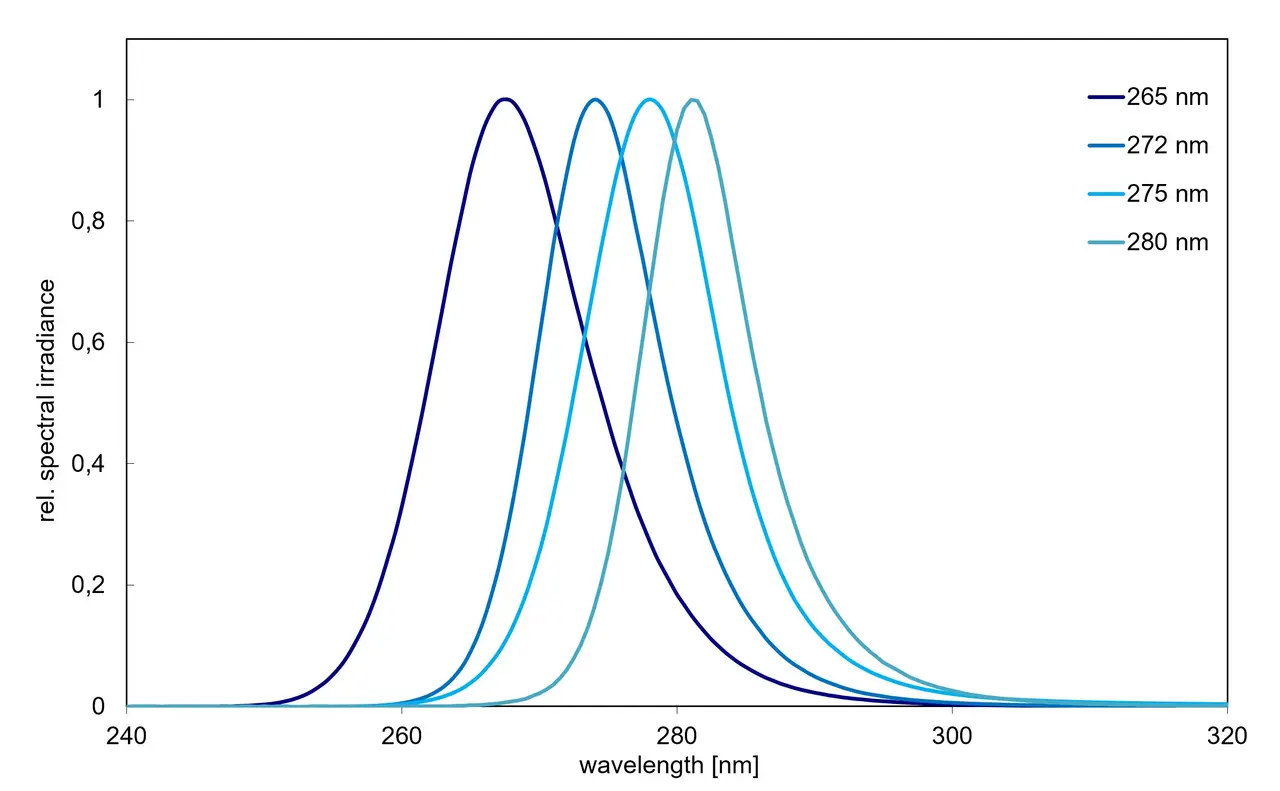

For disinfection applications, we also offer UVB and UVC LED modules with 265 nm, 272 nm, 275 nm, and 280 nm. Ask us!

All LED wavelengths are available in three different light areas ranging from 30 x 30 mm to 100 x 200 mm. Thanks to the modular design, different UV LED heads can be connected to the LEDControl Touch.

A large fan ensures low-noise, stable cooling with minimal thermal drift. For safety-critical applications, the PLready option is available in accordance with EN ISO 13849-1.

APPLICATIONS OF UV-LED LEDCONTROL Touch

- Industrial UV curing and bonding

- IC Encapsulation

- UV sealing

- Hairline / leak detection using fluorescence markers

- Fluorescence Spectroscopy

- Surface Inspection

REMOTE OPERATION of LEDControl Touch

The LEDControl Touch can be controlled via the rear programming interface (USB or RS485) or optionally via a network interface. Communication takes place via Modbus RTU or optionally as ASCII communication with or without checksum (CRC).

Modbus RTU (Remote Terminal Unit) is a serial communication protocol used in industrial automation to connect electronic devices such as sensors, actuators, PLCs (programmable logic controllers), and measuring instruments. Modbus RTU is based on a master-slave principle.

Structure: Address + function code + data field + CRC

The address specifies which slave device is being addressed. The function code defines which operation is to be performed (e.g., read or write). The data field contains, for example, register addresses and values.

ASCII communication is illustrated below using the example “Switch on”:

•Control sends: LOnOff:1!

•LedControl responds: LOnOff: 1 (CRC-16)

Each channel can be controlled individually. LedControl only transmits when requested by the control.

TECHNICAL DATA LEDCONTROL Touch

| Number of UVLEDs | 1,2 or 4 |

| Functions | dimming 2 to 100% |

| timer, continuous operation | |

| Display | capacitive touch display |

| 5“ WVGA / 7“ WVGA | |

| Connections | Enable |

| PLC connections | dimming in (0-10V), common |

| Trigger (IN/OUT), common | |

| PLC connections | Galvanically isolated |

| PLC signals | 24 V, 5 mA max |

| Programming interface | RS485, USB |

| Memory interface | 1 x USB-Stick (up to 32 GB) |

| LAN / Web interface | optional |

| Command set | Modbus RTU / ASCII |

| security monitoring | over temperature, LED N.C. |

| LED error / driver error | |

| Cooling | Aircooling |

| Operating temperature | 5 to 40 °C |

| Storage temperature | -10 to 60 °C |

| Humidity | < 80%, non-condensing |

| Power (el.) | dep. on type, 100 W - 6500 W |

| Mains connection < 2500 W | 100 - 240 V, 50/60 Hz |

| Mains connection >2500 W | 3 x 340-550 VAC, 50/60 Hz |

Functions in detail of the UVA, UVB and UVC LED series and Ledcontrol Touch

The LedControl Touch is operated via a high-resolution capacitive touchscreen. A powerful Cortex ARM processor ensures durability and remote update capability. This allows new functions to be installed directly on site. The LedControl Touch and the PC software are Windows 11 compatible. The fully digital interface communicates with the PC via USB.

Parameterization is intuitive and password-protected. The LedControl Touch can be used in laboratory, pharmaceutical, and industrial environments without any problems. The LedControl Touch records irradiation protocols directly to a USB stick.

The LED power can be set via the PLC interface (0-10V) can be set, the LEDs can be switched on/off (trigger IN 24V) and the status (trigger OUT 24V and error status) can be queried. This PLC interface is suitable for simple system integration using robust, analog signals. Digital control offers further possibilities.

LedControl S is the predecessor of LedControl Touch. The differences in detail are:

Publications at a glance

Our irradiation chambers are used in research, development, and production-

A selection of scientific publications is available here.