Digital PLC UV SENSORS & VIS SENSORS

The PLC.D sensors are ready-to-install UV sensors with digital output. This enables reliable and repeatable irradiance measurements in UV systems. Due to the compact design and the eight spectral ranges, the sensors can be used for a wide range of applications, e.g. in

- packaging facilities

- sterilisation

- surface activation systems

- UV curing systems

- ageing tests

- and many other applications

With the integrated 24-bit ADCs, the PLC.D sensors close the gap between industrial manufacturing and high-precision laboratory equipment. Measurements can be carried out in a simple yet safe way. RS-485 and USB are available as optional connections for this purpose. The data evaluation takes place directly in the PLC.D sensors, the measured values are protected against transmission errors by a CRC-16 check sums. The PLC.D sensors also contain all the information required for complete ISO 17025 or manufacturers calibration.

Various functions such as software triggering, hardware triggering or continuous data transmission can be parameterised via plain text commands.

Example commands:

- DS_MeasResult? Request measurement result

- DS_SerialNr? Request serial number

- DS_Firmware? Request firmware version

- DS_MeasAVG?! Request /Set Averaging

- DS_CalibDate?: Request calibration date

- DS_StartMeas! Command start measurement

- DS_DataMode? Request the measuring mode: Software polling, hardware trigger or continuous

The sensors with RS-485 / RS-232 connection operate with an operating and signal voltage of 24 V and contain a trigger input and data ready output. The sensors with USB connection require no external power supply.

We offer an optional multiplexer. PLC.D Multiplexer connects up to eight PLC.D sensors to a PLC. PLC communication with the PLC.D Multiplexer takes place via RS485. This switches the communication between the connected sensors. This means that only one PLC connection is required. The sensors are connected to the multiplexer via RS232 and supplied by it. The PLC.D Multiplexer is operated with 24 V DC voltage.

HIGHLIGHTS OF PLC.D digital UV SENSORS

- Plain text ASCII communication with check sum

- Direct operation at SPS

- Long-term stable and recalibratable

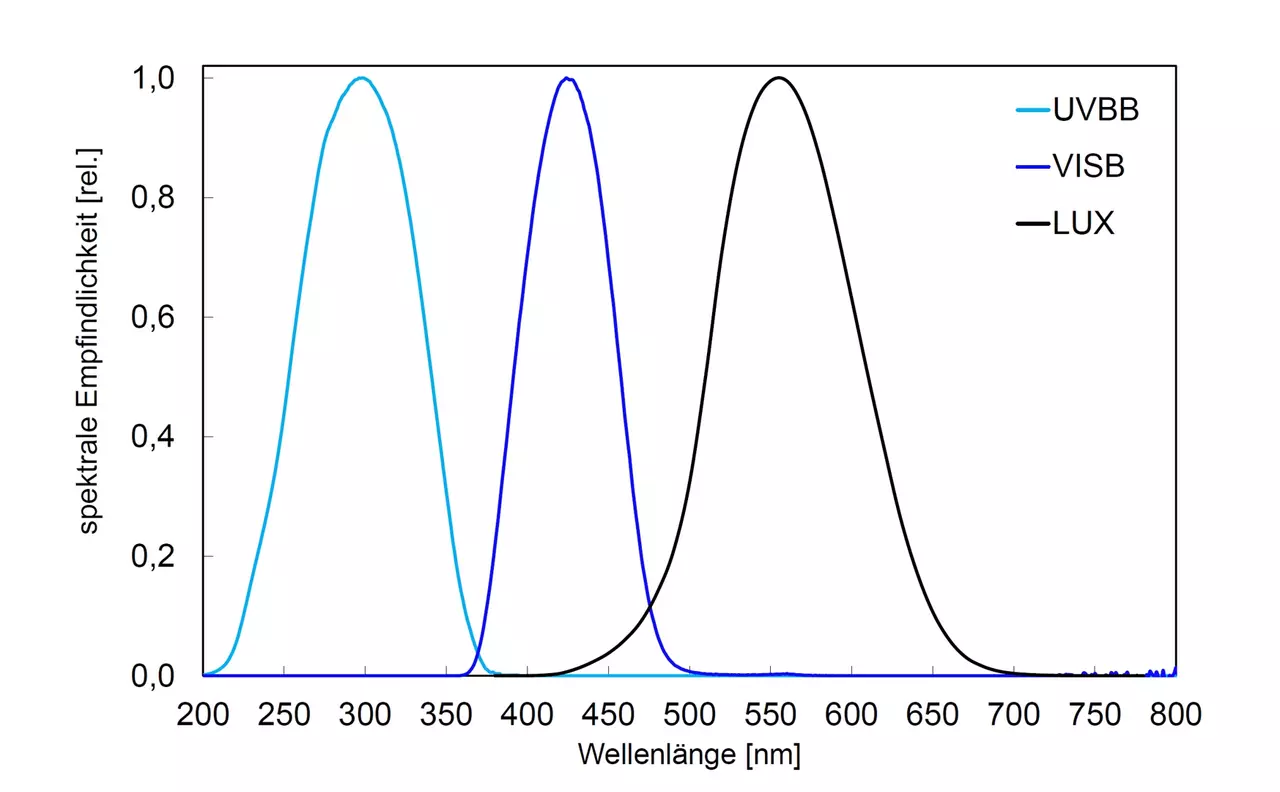

- Eight spectral ranges

- Three measurement modes

TECHNICAL DATA OF PLC.D UV SENSORS with RS-485 and USB

| Operation voltage | 24 V (RS-485 / RS-232) |

| 5 V (USB) | |

| Current input | < 15 mA (RS-485 / RS-232) |

| < 100 mA (USB) | |

| Measuring range | 0 - 10.000 mW/cm² |

| 0 - 10.000 µW/cm² (optional) | |

| Resolution | 0,001 mW/cm² |

| 0,001 µW/cm² (optional) | |

| Dimensions | 80 x 40 x 20 mm |

| Weight | 150 g |

| Connector | Built-in plug, M8, 8-pin |

| Phoenix Contact #1523492 | |

| SACC-DSI-M8MS-8CON-M8/0,5 | |

| I/O, RS-485 / RS-232 | Trigger-In, Dataready |

| I/O, USB | none |

| Operation temperature | 0 to 60 °C |

| Storage temperature | -10 to 60 °C |

| Humidity | < 80% non-condensing |

| Communication | 115200 baud, 8 databit, |

| 1 Stop bit, no parity | |

| RS-485: FULL-DUPLEX | |

| Response time, typical | 60 ms |

| Response time, max | 200 ms |

IS THE PLC.D UV SENSOR SUITABLE FOR TAPE APPLICATIONS SUCH AS UV CURING AND DISINFECTION?

Permanent monitoring of the lamps with permanently installed UV sensors ensures precise control. This is known as inline monitoring. A dose and irradiance can optionally be calibrated using the curelog or UVpad, which are placed directly on the belt due to their design.

Can I use the PLC.D UV sensors to measure PWM-dimmed LEDs and pulsed fluorescent lamps?

The PLC.D UV sensors are suitable for measuring PWW (pulse width modulation) dimmed LEDs. Internal averaging means that the time average of the irradiance is output precisely. For the same reason, however, individual pulses or flashes cannot be measured.

How often do UV sensors need to be calibrated?

We recommend recalibration every 12 months. To do this, send the PLC.D UV sensors back to us. Ideally, you should obtain a current quotation before returning them to us. Once we have received the order and the PLC.D UV sensor, we can start the recalibration process straight away. We usually need 1 week for factory calibrations and 2-3 weeks for ISO 17025 calibrations.