UV CURING CHAMBER BSM-03

The BSM-03 UV curing chamber with an output of 2 kW is best suited for large-area UV curing, hardening, and bonding. The internal shutter is controlled by the UV-MAT for an accurate dose so that reproducible exposure is achieved even with medium-pressure lamps. With irradiance of 150 mW/cm², the required dose is typically achieved within several seconds.

The UV curing chamber can be opened for loading and unloading while the lamp is on. The shutter is monitored and closed with a safety circuit so that no UV radiation is emitted outside the chamber. The sliding sample support also facilitates loading and unloading. It withstands all loads up to 20 kg. With 60 x 40 cm at the base and a height of 25 cm, the irradiation room offers plenty of space. The sample chamber temperature is about 45°C in operation. Due to the high uniformity of the irradiation, the samples may be positioned in any order.

APPLICATIONS OF UV CURING CHAMBER

- UV curing

- UV sealing

- UV bonding

- UV gluing

- surface activation

TECHNICAL DATA UV CURING CHAMBER BSM-03

| Interior chamber | 60 x 40 x 25 cm |

| Dimensions | 77 x 62 x 80 cm |

| Weight | ~ 80 kg |

| Power consumption | 2200 W (irradiation) |

| 850 W (stand-by) | |

| Mains | 3 x 230/400 VAC, 16 A, CEE 400V 16A |

| Power factor | 0,9 |

| Operation temperature | 15 to 30 °C |

| Humidity | < 80%, non condensing |

| Lamp lifetime | 1.000 h to 3.000 h, typical |

| Number of lamps | 1 piece |

| Sample temperature | 45 °C +/- 10 °C |

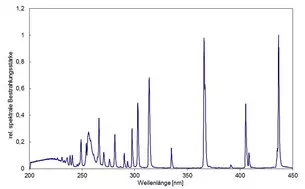

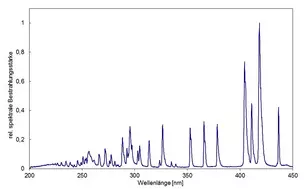

| Spectra ranges | 1 Standard, 2-4 optional |

| Irradiance | up to 150 mW/cm² |

| Available lamps | HG, Fe, Ga |

| Shutter control | Pneumatic, 4-6 bar |

| Cooling | 1 x DN 100 |

Zubehör

Publications at a glance

Our irradiation chambers are used in research, development, and production-

A selection of scientific publications is available here.