UV meter und radiometer

Specialised UV measuring devices are used for the precise detection of optical radiation in the ultraviolet spectral range. They are used to quantitatively analyse UV radiation as it occurs in curing processes, materials testing or environmental protection. The measurement of UV radiation under standardised conditions is crucial for reproducible results.

The RM series offers high-resolution measuring devices for light in the UV range. Depending on the area of application, you can choose between different sensors that are adapted to specific spectral ranges. UV meter measure light and radiation. Our hand-held radiometers RMD and RM-12, as well as panel meters RM-31 and RM-32, are precise UV instruments with external uv sensors. The sensors can be exchanged and adapted to the application. With eight standard spectral ranges, we offer the right sensor for most applications.

For measurements in UV belt systems, the uv sensors are built into tinyTracker and TrackerUSB. Here the UVpad is ideally suited for measurements and comparison of UV lamps and UV LEDs. With its innovative spectral measuring principle, it doesn't use optical filters.

Did you know?

Between 1997 and summer 2022, an RM-11 radiometer with sensors for UV-A and UV-B was exhibited in the environmental exhibition (view) in the Deutsches Museum in Munich. The building is currently being renovated. We are very pleased about this 25-year presentation and are proud of this success.

What are UV meters and how do they work?

Every UV radiation measuring device from Opsytec Dr Gröbel is based on calibrated detector units with defined spectral sensitivity. The devices enable linear and traceable measurement of UV radiation in accordance with international standards.

UV meters are instruments used to measure the intensity and wavelength of ultraviolet radiation. These devices play a crucial role in many industrial and scientific applications. One of the most advanced models on the market is the RMD Pro from Opsytec Dr. Gröbel. This device provides precise measurements and is ideal for applications that require the highest accuracy.

With a high-quality UV meter, you can effectively measure the intensity of UVA, UVB or UVC radiation. Our UV meters provide you with reliable data and help you to monitor UV processes and minimize the risks of UV radiation.

Different UV meter classes: Broadband radiometer and spectroradiometer

The most important classes of UV meters include broadband radiometers and spectroradiometers.

Broadband radiometers are UV meters that measure the entire bandwidth of a specific UV spectral range (UVA, UVB or UVC). These devices use optical filters that selectively transmit certain wavelength ranges and block others, as well as detectors. Broadband radiometers thus record the UV radiation within a wavelength range and provide a sum value of the radiation intensity, called irradiance.

Spectroradiometers are UV meters that measure the intensity of UV radiation with spectral resolution over a specific wavelength range. In contrast to broadband radiometers, spectroradiometers can determine the intensity at individual wavelengths or in very narrow wavelength bands.

Spectroradiometers use an optical spectrometer that splits the UV light into its spectral components. This is often achieved using a grating or prism. CMOS lines and CCDs or photomultipliers are used as detectors. The spectrometer selects the wavelengths, which are then recorded by the detector and converted into electrical signals.

Applications of the UV meter

While broadband radiometers offer a simple and effective solution for measuring overall intensity, spectroradiometers allow detailed spectral analysis.

Broadband radiometers are ideal for applications where the total intensity of UV radiation in a specific spectral range is of interest, such as

- Curing of coatings and adhesives: Measurement of the total UV intensity to optimize the curing processes.

- Solariums and medical therapies: UV dose monitoring to ensure safe and effective treatments.

- Environmental monitoring: Determination of UV exposure in the atmosphere for environmental studies and protective measures.

Spectroradiometers are suitable for applications where a detailed spectral analysis of UV radiation is required. This includes determining the spectral emission of UV lamps and LEDs when lamps change depending on temperature or ageing. Spectroradiometers are also advantageous when many different lamps or UV LEDs are to be measured.

Comparison and selection criteria for UV meters

The following factors should be considered when selecting the appropriate UV meter class for a particular application:

- UV meters with filters are more sensitive than spectroradiometers and are therefore advantageous for measurements at low irradiances & intensities.

- For applications that require an overall assessment of UV intensity, broadband radiometers are sufficient. However, if detailed spectral information is required, spectroradiometers are the better choice.

- Spectroradiometers offer higher spectral resolution and accuracy compared to broadband radiometers, but are generally more expensive and more complex to use.

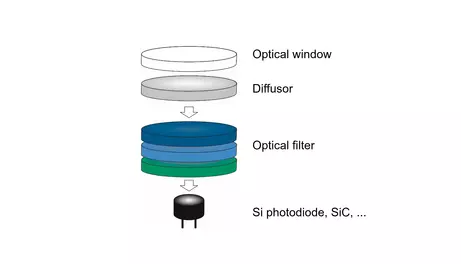

Components of a UV meter

UV meters work by using filters and sensors that convert ultraviolet radiation into electrical signals. These devices use components such as diffusers, filters, photodiodes and analog-to-digital converters to provide accurate readings. Here is a detailed explanation of how they work and the technologies used.

Diffusers

Diffusers are used to scatter the incident UV light evenly. This is particularly important in order to correct directional dependence and is known as cosine correction. The diffusers are often made of opaque quartz glass, which contains extremely small gas bubbles as scattering centers, or PTFE

Filter

Filters select specific wavelengths of UV light in order to isolate the desired UV bandwidth (UVA, UVB or UVC). Various types of optical filters, such as interference filters, absorption filters as bandpass or longpass filters are used.

These filters are selected by the manufacturer and are matched to the applications of the UV measuring device.

Photodiodes

Photodiodes are the main sensors in UV measuring devices that convert UV radiation into electrical signals. Photodiodes consist of semiconductor materials such as silicon or silicon carbide. These materials react to UV radiation and generate a current proportional to the intensity of the incident UV radiation.

Analog-to-digital converter (ADC)

The analog-to-digital converter converts the analog signal generated by the photodiode into a digital signal that can be further processed by microprocessors.

ADCs work by sampling the analog signal and converting it into digital values with high precision. The resolution of the ADC (e.g. 12-bit, 16-bit or 24-bit) influences the accuracy and fineness of the measured values. High resolutions of 24-bit are therefore preferable.

Measured values from UV meters

UV meters provide different types of measured values that are relevant for different applications. The most important measured values include

- Irradiance = intensity of UV radiation: This is measured in units such as watts per square meter (W/m²), mW/cm² or microwatts per square centimeter (µW/cm²). The intensity indicates how strong the UV radiation is in a certain area. The reference to an area can be easily converted. For example, 10 mW/cm² also corresponds to 100 W/m² (= 100000 mW/m²).

- Dose of UV radiation: The UV dose is the product of the irradiance of the UV radiation and the exposure time, measured in joules per square meter (J/m²). This is particularly important for applications such as UV curing and disinfection, where the cumulative effect of UV radiation is crucial.

- Spectral distribution: Only spectroradiometers can also measure the spectral distribution of UV radiation.

Tips for choosing the right UV meter

The following criteria should be considered when selecting a UV meter:

- Measuring range and spectral range: Make sure that the device covers the UV range relevant for your application (UVA, UVB, UVC).

- Accuracy and calibration: Choose a device with high accuracy and certified calibration, such as the RMD Pro from Opsytec Dr. Gröbel. All systems can be calibrated regularly to ensure long-term accuracy in the measurement of UV radiation. Calibration is carried out using national standards such as those of the PTB.

- Robustness and reliability: Look for a robust design that works reliably even in demanding environments.

- Support and spare parts: Opsytec Dr. Gröbel offers comprehensive support, availability of spare parts and advice directly from the manufacturer, facilitating long-term reliability and maintenance.

- We usually carry out the factory calibration within a week to minimize downtime. The factory calibration always ensures precise measurements with regard to ageing of the UV measuring device and contamination.

The higher-grade ISO 17025 calibration is an internationally recognized standard that ensures the competence of calibration laboratories. Opsytec Dr. Gröbel offers ISO 17025 certified calibrations for a wide range of UV measuring devices. The ISO 17025 calibration offers higher accuracy of measurements due to lower calibration uncertainties and guarantees the recognition of the UV measurement device calibration.

Differences and applications of the various UV meters

Ultraviolet radiation is divided into three main spectral ranges: UVA, UVB and UVC. Each of these spectral range has specific properties and applications.

UVA

- Wavelength range: 315-400 nm

Applications: Curing of coatings and adhesives, disinfection, phototherapy, and detection of fluorescence.

UVB

- Wavelength range: 280-315 nm

Applications: Medical therapies such as the treatment of skin diseases, sterilization and photochemistry.

UVC

- Wavelength range: 200-280 nm

Applications: Germicidal and disinfection, air and water purification, and in the food industry for sterilization.

Use of UV meters

In industrial processes - for example in the curing of UV adhesives - continuous monitoring of UV radiation is essential. UV measuring devices are also used in the medical field to monitor irradiation doses.

UV meters offer numerous advantages in various industrial and scientific fields:

- Quality assurance in the production of materials, curing of coatings and adhesives, and monitoring of disinfection processes.

- Precise dosing of UV therapies, sterilization of medical devices.

- UV exposure monitoring, research on the impact of UV radiation on the environment.

- Investigation of photochemical reactions, development of new materials and technologies.

- Irradiance of lamps and irradiation systems

- Measurement of UV lamps, UV LEDs & light sources

- Dose measurements in conveyor systems and during UV ageing

- Process control of UV curing and UV bonding

- Measurement for workplace safety

- Quality assurance

Application tips and best practices for UV measurement devices

Get the most out of your UV measuring device with a few application tips:

- Position your UV meter at a location where the application will take place. The irradiance depends on the distance. Therefore, the UV measuring device should be positioned exactly at the desired location. This is, for example, the bonding point for UV bonding or the position of the facial skin for workplace measurements.

- Make sure you use the right calibration lamp. An important aspect of UV measurement is spectral mismatch. This occurs when the spectrum of the calibration lamp does not perfectly match the spectrum of the UV lamp to be measured. For our high-quality UV measuring devices such as the RMD Pro, we minimize these mismatches through application-oriented calibration procedures and have a wide range of calibration lamps available.

- Protection from soiling: Protect the device from soiling to ensure a long service life. If the UV measuring device is dirty, we recommend cleaning it carefully with isoproanol and a lint-free cloth.

- Regular calibration: Calibrate your UV measuring device regularly to ensure precise data at all times and to prevent contamination and ageing.

Use these tips to optimize the use of your radiometer and ensure reliable measurement results!

Our customer service team is on hand with help and advice if you have any questions or need assistance with the set-up. Rely on Opsytec Dr. Gröbel's many years of experience and expertise to meet your UV measurement requirements in the best possible way.

Don't know how to choose the right sensor? Maybe our application notes can help.