Spectral mismatch for UV sensors

In contrast to illuminance meters, UV sensors are designed for different spectra and different spectral ranges. To ensure that a UV sensor has the desired spectral sensitivity, manufacturer-specific optical filters are used to adjust the spectral sensitivity.

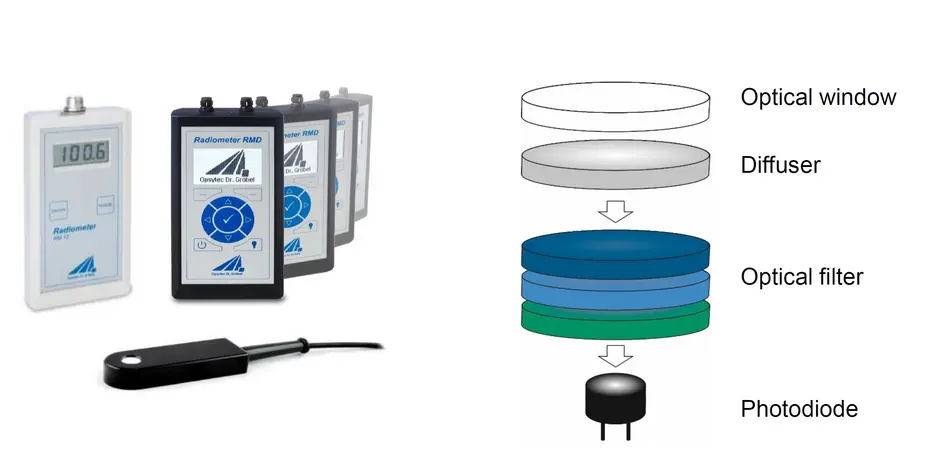

The following image illustrates the structure of a UV sensor or radiometer, which is typically used to measure ultraviolet radiation. The sensor consists of several optical filters and a photodiode. The other electrical components, the amplification and analog-to-digital conversion are not shown here.

Ideally, the sensitivity curve corresponds to a constant, rectangular weighting function. In practice, however, deviations occur - the so-called spectral mismatch. This describes the difference between the actual sensitivity of the sensor and the ideal weighting function.

The reasons for this are typical for all filtered UV sensors, as the optical filters used do not have ideal cut-off and pass ranges or "infinitely" steep filter edges. Photodiodes also show a typical spectral sensitivity.

Influence of spectral sensitivity

The spectral sensitivity is a characteristic device property of every UV sensor. While sensors of the same type show similar characteristics, different sensors - depending on the manufacturer, type and spectral range - differ significantly.

The measured value of a UV sensor depends heavily on the emission spectrum of the light source. A sensor calibrated to a specific source (e.g. mercury vapor lamp or UV LED) can show significant deviations with a different source.

The result of the spectral mismatch is a source-dependent measurement uncertainty. For example, if a sensor is calibrated with a broadband lamp but used with a narrowband UV LED, the displayed value can deviate from the actual effective value by several tens of percent. These deviations are reproducible and therefore systematic in nature.

Example of a spectral mismatch

A UV sensor has a real weighting function (gray), while the ideal curve (black) describes a uniform response.

For a 400 nm LED, the relative sensitivity is 1.0.

For a 425 nm LED, the relative sensitivity drops to 0.9.

The displayed value is therefore around 10 % smaller. Modern measuring devices such as the RMD radiometer compensate for this effect internally, provided the respective lamp type (e.g. 400 nm or 425 nm) is selected correctly.

Methods for reducing spectral mismatch

1. source-dependent calibration

At Opsytec, UV sensors are calibrated to the actual lamp or LED used for the specific application. Numerous industrial UV sources are available in the laboratory for this purpose in order to adjust the calibration precisely to the desired spectral range.

2. mathematical correction

With modern radiometers, the calibration factor can be saved directly in the sensor. The appropriate calibration range - e.g. 365 nm for UVA LEDs or 450 nm for blue LEDs - is simply selected on the measuring device. For older or external systems, Opsytec can determine a correction factor, which is specified in the calibration certificate.

3. use of spectroradiometers

Spectroradiometers capture the complete spectrum and are free of spectral mismatch. The wavelength-specific calibration means that any deviation is corrected by calculation. The UVpad and UVpad E models are particularly suitable for mobile use.

Importance for precise UV measurements

Knowledge and correction of the mismatch is therefore a prerequisite for reliable UV measurements, especially in applications with narrow-band or spectrally variable sources such as UV LED systems. We have the sources or UV sensors and spectroradiometers available to us in the laboratory for this purpose.

It is important to know that the spectral adjustment can be corrected very well if only one UV lamp is to be measured. Simply inform us of the lamp to be measured or the application.

For example, a low-pressure mercury lamp is often used as a calibration source for detectors used in disinfection. Calibration is carried out, for example, in the spectral range 200-280 nm or 240-290 nm.

Although this effective spectrum covers a wide range of wavelengths, in practice only the 253.7 nm line of the mercury lamp is usually used to determine the sensitivity of the UV radiometer for this single spectral line.

The result of this calibration thus provides a calibration value for a specific operating condition, but without providing information about the spectral sensitivity of the detector.

If you want to measure many different UV lamps and UV LEDs, we recommend a spectroradiometer.

For the interested reader:

Calibration standards and norms

The spectral mismatch is described in international standards, in particular in CIE 220:2016 - Characterization and Calibration Methods of UV Radiometers.

The recommendation is to match the calibration source as closely as possible to the actual light source of the application.

For applications with multiple UV lamps or UV LEDs, Opsytec recommends the use of a spectroradiometer to fully capture and evaluate the emission spectrum.