Collimated Beam Device BSH-03 CBD

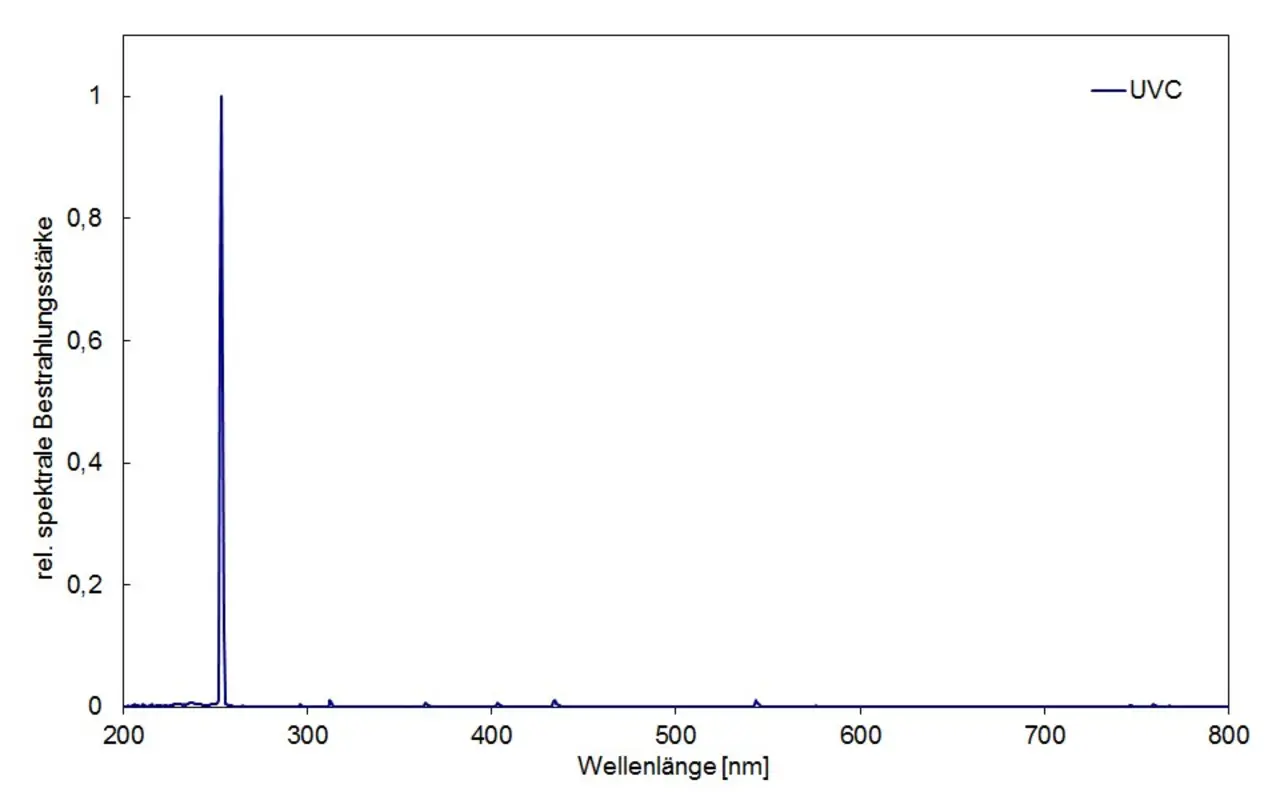

The BSH-03CBD is a precisely engineered collimated beam irradiation chamber for reproducible and dose-accurate UV irradiation of liquid samples. With three 150 W UVC amalgam lamps, it ensures a homogeneous, high-intensity 254 nm radiation source. The system was developed based on the standard methods for fluence and dose determination described in the technical literature according to Bolton & Linden, Standardization of Methods for Fluence “UV Dose Determination in Bench-Scale UV Experiments” (2003) – the methodology that is considered the reference in scientific UV disinfection research.

The procedure was adopted in DIN 19294-1:2020-08, so that the BSH-03CBD can be used to determine the average fluence rate in the spore suspension.

The inactivation must be carried out in a BSH-03CBD in accordance with Annex D of DIN 19294-1:2020-08.

The chamber can also be opened safely during active operation to load and unload samples. The internal shutter is controlled by the UV-MAT to ensure precise dosing. Safety monitoring ensures that no UV radiation escapes outside the chamber.

The BSH-03CBD irradiation chamber is therefore a reliable and precise solution for scientific research and industrial applications of UV disinfection. Its robust construction, safety, and user-friendly operation make it an indispensable tool in water treatment and chemical analysis.

Key features:

- The BSM-03CBD is equipped with three ozone-free 50 W UVC amalgam lamps. These lamps ensure uniform and high UV irradiation.

- A robust and secure protective housing ensures safe operation and protection from UV radiation.

- The large irradiation area is suitable for customer-supplied Petri dishes and magnetic stirrers for continuous mixing of the liquid.

- A UV reference sensor for dose-controlled operation is built in.

- A second UVC sensor allows for easy setup of the system.

- The UV-MAT Touch allows for easy handling and monitoring of the irradiation process.

- Monitored & interlocking door: Safety mechanisms prevent the emission of UV radiation when the door is open.

- A base plate with screw threads allows easy measurement of the irradiation field and adjustment of the sample position.

- Pneumatic, automated plate shutter: For precise control of the irradiation duration

- Operating hours counter for monitoring lamp life and planning maintenance.

- PC software for storing raw data and short reports (PDF), including user management and password protection (2 user levels).

It is particularly suitable for applications in the field of UV disinfection and for carrying out scientific experiments to investigate the effects of water treatment processes on residues of active substances or their metabolites.

Based on UV irradiation using the colimated beam principle, the effects of water treatment processes on residues of active substances or their metabolites can be analyzed. This includes in particular the formation of transformation products (TPs).

The BSM-03CBD is ideal for carrying out UV disinfection tests and irradiating samples under controlled conditions. The radiation is emitted vertically downwards and illuminates the suspension evenly with the aid of a apertures.

In a continuously stirred volume of e.g. 150 mL and a water depth of 1.6 cm, samples can be treated with an exact UV dose of 100 mJ/cm².

With its high irradiance of a few mW/cm², the BSM-03CBD achieves the required UV dose in typically a few seconds to two minutes, enabling fast and efficient treatment of samples.

The chamber can also be safely opened during active operation to load and unload samples. The internal shutter is controlled by the UV-MAT to ensure exact dosing. Safety monitoring ensures that no UV radiation escapes outside the chamber.

The BSM-03CBD irradiation chamber is therefore a reliable and precise solution for scientific research and industrial UV disinfection applications. Its robust design, safety and user-friendly operation make it an indispensable tool in water treatment and chemical analysis.

Main features of the collimated beam device:

The BSM-03CBD is equipped with an ozone-free medium pressure lamp with an output of 1 kW. This lamp ensures uniform and high UV irradiation.

A robust and safe protective housing ensures safe operation and protection against UV radiation.

The large irradiation area is suitable for customer Petri dishes and magnetic stirrers for continuous mixing of the liquid.

- Reference UV sensor for dose-controlled operation to ensure precise UV doses

- A 2nd UV sensor enables easy system set-up

- The UV-MAT Touch allows easy handling and monitoring of the irradiation process

- Monitored & locking door: Safety mechanisms prevent the emission of UV radiation when the door is open.

- A base plate with screw threads allows easy measurement of the irradiation field and adjustment of the sample position.

- Leveling feet for precise, horizontal alignment of the chamber

- Pneumatic, automated plate shutter: For precise control of the irradiation time

- Operating hours counter for monitoring lamp life and planning maintenance.

- PC software: For data storage of raw data and short reports (PDF), incl. user administration and password protection (2 user levels).

TECHNICAL DATA UVC Collimated Beam DEVICE

| Interior chamber | 60 x 40 x 25 cm |

| Dimensions | 130 x 62 x 76 cm |

| Weight | ca. 65 kg |

| Power consumption | 550 W |

| Mains | 230 VAC, 6 A |

| 3 x110/208 VAC, 8 A, optional | |

| Operation temperature | 15 to 30 °C |

| Humidity | < 80% non-condensing |

| Lamp lifetime | 3.000 h to 5.000 h, typical |

| Number of lamps | 3 |

| Lamp type | 150 W UVC amalgam lamps |

| ozone free | yes |

| Sample temperature | Room temperature + ~ 1-2°C |

| Shutter control | Pneumatic, 4-6 bar |

| Cooling | 1 x DN 100 |