UV AOP chamber BS-OX

The BS-OX irradiation chamber enables targeted UVC irradiation in an oxygen-reduced atmosphere for photochemical surface cleaning, ozone treatment, and targeted contact angle modification.

The technological basis is a high and homogeneous UVC irradiation intensity, supplemented by time-controlled irradiation, integrated measurement programs for routine measurements of the irradiation intensity, a compact design, and a large-volume sample chamber.

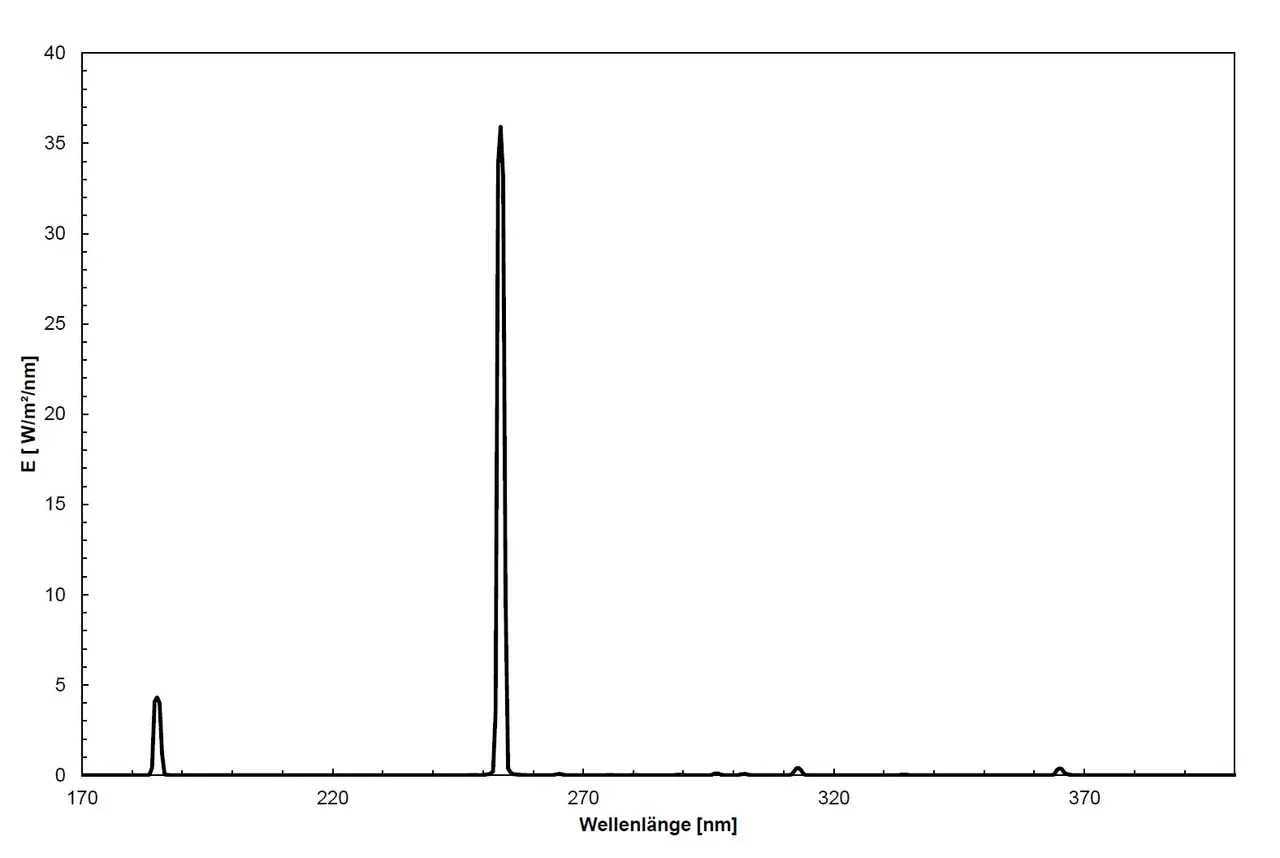

Photochemical cleaning and activation with 185 nm UVC in an oxygen-reduced atmosphere leads to ozone formation and the generation of reactive oxygen species. These efficiently oxidize organic contaminants and increase surface energy. This results in improved wettability and a reproducible reduction in the contact angle.

At the same time, the UV radiation is energetic enough to split organic compounds, for example.

The 185 nm spectrum is used for ozone and radical formation as well as direct photolysis of organic residues.

The 254 nm wavelength also enables classic UVC processes such as disinfection and pretreatment for coating processes.

The BS-OX can operate with 8 ozone-free or ozone-generating UVC lamps. A mixed configuration in a 4+4 ratio allows for optional operation with an ozone-containing or ozone-free process atmosphere, thus supporting precise control of cleaning, oxidation, and surface activation.

All internal surfaces are made of uncoated metals and quartz glass. Organic coatings or polymer-based protective layers are completely dispensed with. This means that there are no degradation products and no outgassing under 185 nm/254 nm irradiation. The result is a process chamber with stable boundary conditions for surface cleaning, ozone treatment, and reproducible contact angle changes.

The BS-OX is designed for industrial and scientific applications in which organic residual films, photoresist residues, or adsorbates limit the functionality of components.

Fields of application for AOP chamber BS-OX

- Activation of polymer, glass, ceramic, and metal surfaces prior to bonding, sealing, or coating

- Cleaning of optical components, wafers, microchips, and filters with subsequent increase in the polar surface area

- Adjustment of contact angle and surface energy for microfluidics, medical technology, and sensor technology

- Sterilization and degradation of odor- or color-active organic contaminants

Dual irradiation at 185 nm and 254 nm enables reliable degradation of organic residues through photolysis and downstream ozone/oxidation & radical reactions.

At the same time, the polar portion of the surface increases, which defines the wettability and contact angle.

Based on the proven BS irradiation chamber platform, a homogeneous, high-performance UVC sample chamber with generous internal dimensions is available. Short process times, moderate sample temperatures, and flexible lamp configurations qualify the BS-OX as a robust system for research, development, and production, especially in semiconductor and optics manufacturing as well as in the surface pretreatment of modern materials.

Technical data of AOP chamber BS-OX

| Interior chamber | 50 x 30 x 25 cm |

| Dimensions, chamber | 81 x 59 x 63 cm |

| Dimensions, UV-MAT | 19 x 25 x 10 cm |

| Weight | ~ 60 kg |

| Irradiation time | 0,01 s to 9999 h |

| Power consumption | 225 W |

| Mains | 230 VAC, 2 A |

| Operation temperature | 10 to 40 °C |

| Humidity | < 80% non-condensing |

| Lamp lifetime | up to 8.000 h |

| Number of lamps | 8 |

| Lamp type | UVC, ozone generating |

| alternative: ozone free | |

| Lamp power | 20 W each |

| Sample temperature | 45 °C +/- 5°C |

| Gas inlet / Gas outlet | Festo QSK-G1/4-10 for |

| 10 mm hose diameter | |

| Exhaust air | DN 100 connetor for |

| Corrugated metal hose and | |

| suitable exhaust air treatment | |

| Classification | Group 0 acccording to |

| DIN EN 12198:2000 |